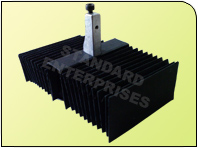

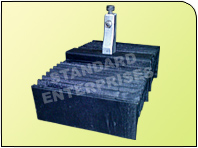

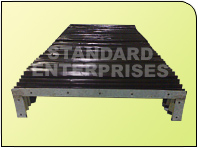

C Type Nylon Plastic Bellows

C Type Nylon Plastic Bellows typically refer to protective covers for moving parts in machinery, often used to protect guideways and spindles, especially in machine tool applications. These bellows act as barriers against dust, chips, and other contaminants while still allowing for movement of the machinery parts they cover. Nylon, given its durability and resilience, is a common material choice for such bellows.

C Type Bellows are designed to protect precession Guideways of M/C. From coolent, Dust, and Metal Chips. Thease bellows are used for covering guideways of CNC machines the / Cylindrical Grinding Machines.

Features and Characteristics of C Type Nylon Plastic Bellows

- Material : Made of Nylon (or sometimes other plastics), which ensures durability and resistance against wear and tear.

- Flexibility : These bellows can compress and extend, allowing for machine part movement.

- Protection : Effective in protecting machinery parts from contaminants such as dust, dirt, and metal or wood chips.

- Temperature Resistance : Nylon can typically resist moderate temperatures but may not be suitable for extremely high-temperature applications.

- Application : Often used in machinery like CNC machines, lathes, milling machines, and other equipment where moving parts require protection.

- Design : The "C Type" might indicate a specific design or way of folding that the bellow follows. This can be unique to the manufacturer or the specific application needs.

- Easy Installation : Typically, they can be installed without any requirement for special tools.

- Lifespan : While nylon bellows are robust and durable, their lifespan will depend on the operating conditions they're exposed to. Regular inspections can help ensure they're still functioning effectively and replace them when necessary.

When selecting a C Type Nylon Plastic Bellow, one should consider

- The size and dimensions needed for your application.

- The operating environment (e.g., temperature, type of contaminants).

- Expected frequency and speed of movement.

- Any specific design or customization needs.

For specific product details, it would be best to refer to a manufacturer's catalog or speak to a sales representative who can provide in-depth information and recommendations based on your needs.

C Type Nylon Plastic Bellows application industries

Nylon (often referred to as Polyamide) bellows, especially the "C Type," are used in various industries for multiple applications due to their unique properties such as high tensile strength, good elasticity, excellent abrasion resistance, and resistance to many oils and chemicals. Here are some industries and applications where these bellows are utilized

- Machine Tool Industry

- Used as protective covers for machine guideways, spindles, lead screws, and other moving parts.

- Protects the machine components from dust, metal chips, and coolants, increasing the lifespan of the equipment.

- Medical Equipment

- Protects sensitive parts of medical instruments from contamination.

- Used in devices like surgical tools, where cleanliness and sterility are paramount.

- Robotics and Automation

- Protects robotic arms and components from dust, debris, and other contaminants that could affect their performance.

- Material Handling Equipment

- Used in conveyor systems to protect moving parts from dirt and debris.

- Prevents foreign particles from entering sensitive areas, ensuring the safe and efficient operation of the equipment.

- Aerospace and Defense

- Protects sensitive equipment from harsh environmental conditions.

- Ensures that mechanical systems function optimally by preventing ingress of unwanted particles.

- Automotive Industry

- Used to shield automotive components from road debris, water, and other contaminants.

- Ensures longevity and efficient operation of automotive systems.

- Printing and Packaging Industry

- Prevents dust and particles from affecting the printing quality.

- Ensures that packaging machinery operates smoothly without interruption.

- Electronics and Semiconductors

- Protects sensitive electronic components from dust and particles.

- Ensures clean environments for semiconductor manufacturing.

- Food and Beverage Industry

- Used in machinery to prevent contaminants from affecting the food production process.

- Made of food-grade materials and helps in maintaining hygiene standards.

- Marine Applications

- Protects equipment from saltwater, ensuring that marine systems operate without corrosion or damage.

- Railway and Transport

- Shields components from dust, debris, and environmental conditions, ensuring the smooth operation of transport systems.

In general, nylon bellows serve as barriers against external contaminants, ensuring that machinery and equipment operate efficiently and have extended lifespans. It's worth noting that the specifications and properties of nylon bellows might vary based on the particular industry and its requirements. When selecting nylon bellows for a specific application, it's essential to consider factors like the operating environment, temperature range, chemical resistance, and mechanical stresses.

Installation of C Type Nylon Plastic Bellows

Installing C Type Nylon Plastic Bellows involves a few standard steps. These bellows are commonly used to protect moving parts, such as rods or shafts, from dirt, dust, and other contaminants. Here's a general guide for their installation

- Preparation

- Ensure you have the correct size and type of bellow for your application.

- Clean the area of installation to make sure no contaminants are present.

- Check the Bellow

- Examine the nylon bellow for any damage or defects.

- Stretch it out to ensure it can move freely without any obstructions.

- Installation

- Fixed End

- Identify the fixed end of your application (the end that will remain stationary).

- Attach the bellow to the fixed end using the provided fastening method. This might be clamps, screws, or other fastening mechanisms.

- Moving End

- Stretch the bellow toward the moving end.

- Ensure that the bellow isn't over-extended or too compressed. It should have some slack to accommodate the range of motion of the application.

- Attach the bellow to the moving end, similar to the fixed end.

- Fixed End

- Test the Motion

- Move the equipment through its full range of motion to ensure the bellow doesn't bind, pinch, or stretch excessively.

- Adjust as necessary if you notice any issues.

- Routine Checks

- It's essential to periodically inspect the bellow for any wear, damage, or obstructions.

- Ensure that no contaminants like dirt or debris have entered the bellow.

- Maintenance

- Clean the bellow occasionally to ensure it's free of dust and debris.

- If you notice any damage or wear, consider replacing the bellow to continue providing optimal protection.

Always refer to the manufacturer's instructions and guidelines when installing specific products. The steps mentioned above are a general guide and might differ based on the exact product and application.